-

No.2 Hongwandao road Wuqing Tianjin China

-

Contact us 0086-400-086-3628

-

Email sales@polyvalley.com.cn

No.2 Hongwandao road Wuqing Tianjin China

Contact us 0086-400-086-3628

Email sales@polyvalley.com.cn

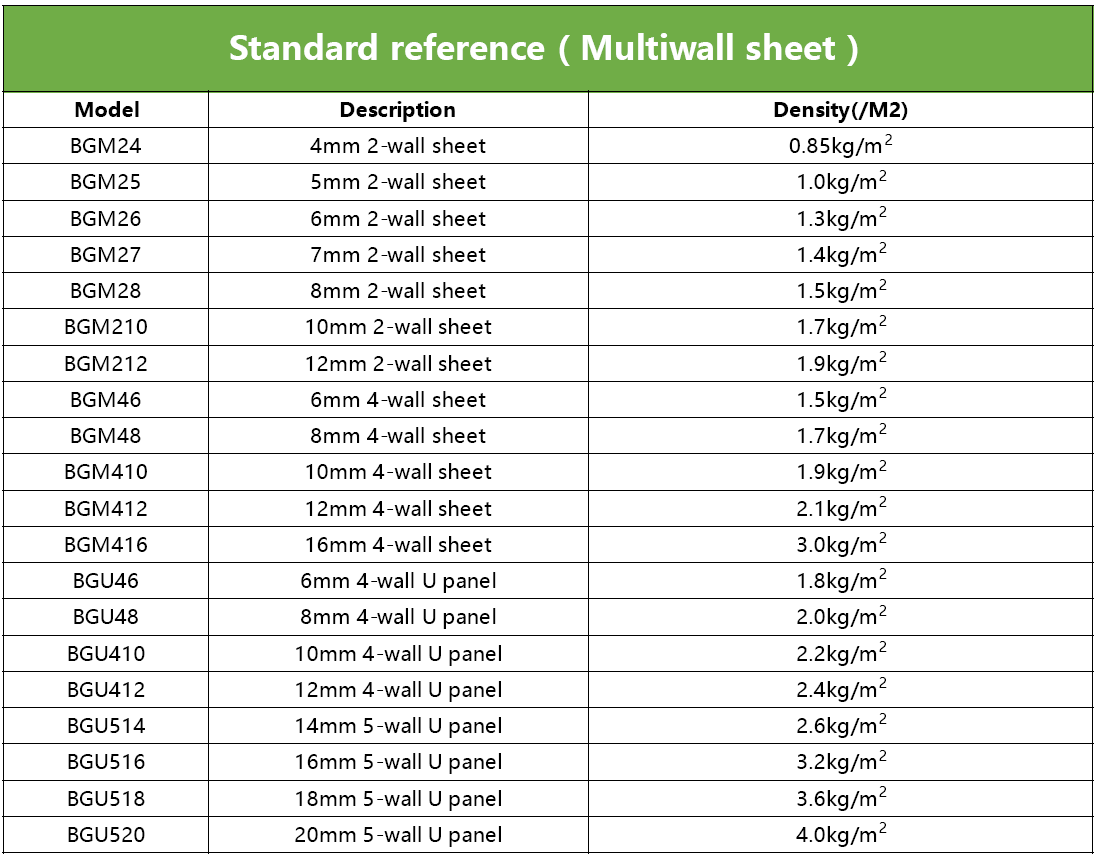

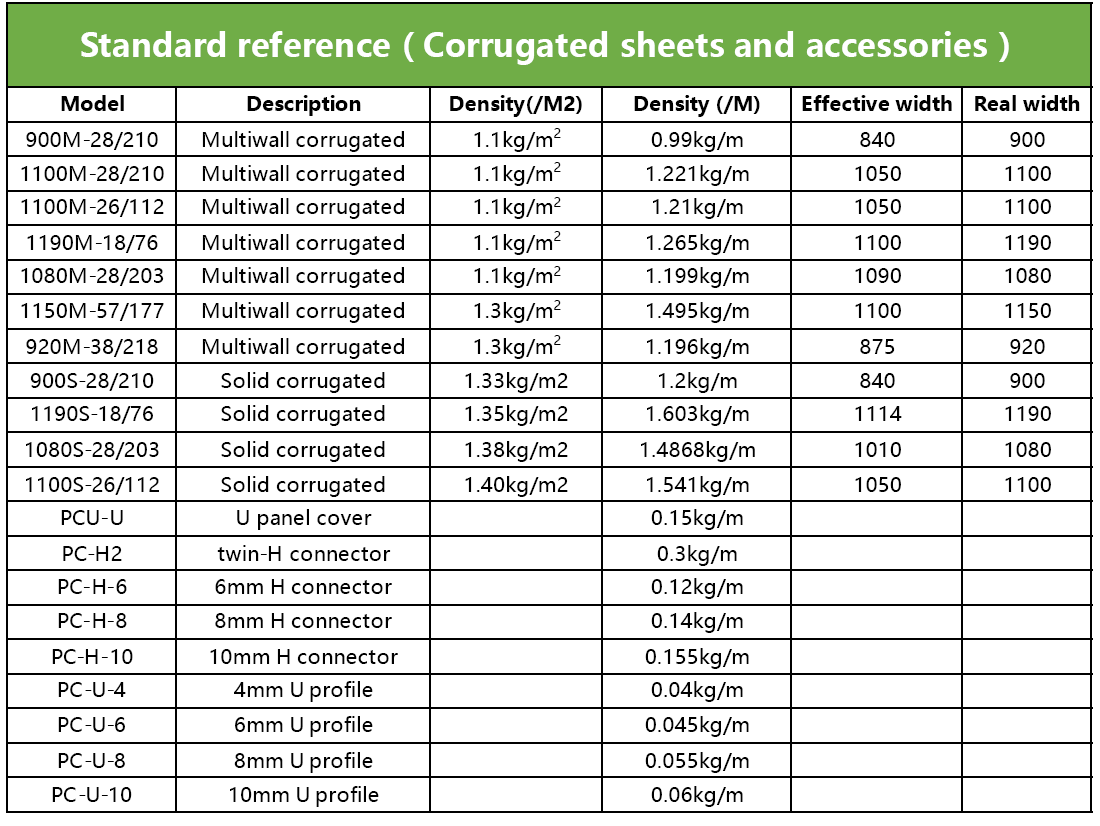

Note: The above standard is just for reference. We can manufacture according to your requirement. Please confirm the standard you wanted before confirming the order

Yes, Polyvalley products are a system meant to provide the best possible installation. Proper use of the complete system (panels, closure strips, fasteners, etc.) greatly reduces the possibility of problems and insures that product warranty will be honored.

Yes, Pre-drilling the holes insures the panels will have room to expand and contract properly with temperature change. Skipping this step can lead to distorted or warped panels.

It's not easy to identify the polycarbonate sheets quality just by eay. All sheets look OK when after produced. But poor quality polycarbonate sheets will change color and be broken when exposed to Sun for 1 or 2 years, while polyvalley sheets can be guaranted for 10 years without yellowing or breakge. There are following points you could use for identify the quality:

1) appearance (shoudl be as clear and possible)

2) Strength (should be as strong as possible)

3) UV coating (The UV coating is with blue color, Checking on the UV coating, the blue the better)

Easily, Polyvalley sheets may be cut with either a circular saw (using a very fine blade, e.g. plywood, etc.) or a jig saw. For best results it is often better to cut a few sheets at a time to reduce vibration. Also, if using a toothed circular saw blade, better results may be seen running the blade backwards. Sheets may also be cut by hand by carefully using tin snips or a utility knife. For further information please refer to our product manuals.

Warm water with a mild household detergent can be used. Wipe off any remained dirt with a soft cloth and wash again. NEVER use a solvent based cleaner (ammonia, etc.). AVOID using sponges or brushes that can scratch the panels surface.

No. In case it can’t be avoided during installation, use stepping ladders or crawling boards.

Store in a protected, shaded, ventilated site, with no direct exposure to sunlight and winds. In outdoor temporary storage cover with opaque protective film, and avoid PVC films and heat-absorbing materials. Please note: Surface protective films that cover sheets are highly sensitive to heat and direct sunlight. Excessive heat and direct sunlight before taking off the film can cause gluing of that film to the sheet surface, after which it will not be practically possible to remove it from the sheet!

The surface films in certain sheets are needed for protection against dirt and scratching, and also used to carry important information to the installer and final customer. The indication of the UV protected side that should be installed facing outwards is extremely important. It is recommended to peel off the protective films only after installation. In case this will not be feasible and the film will be peeled off before laying the sheets, it must be remembered to at least mark the UV protected surface, so that the sheet will not be installed inside out. Please also note: Surface protective films that cover sheets are highly sensitive to heat and direct sunlight. Excessive heat and direct sunlight before taking off the film can cause gluing of that film to the sheet surface, after which it will not be practically possible to remove it from the sheet!

Yes. Sheets can be cold-curved and serve in arched shapes, provided the relevant Polyvalley specifications for minimum radius in cold curving are followed. Solid sheets can be cold-curved in any direction. Corrugated sheets can be arched so that the corrugations themselves are curved (lengthwise). Multi-wall sheets can be arched so that the actual ribs will be curved (lengthwise). Curving is not recommended across the ribs direction.

Yes. In principle all plastic materials are flammable, and will catch fire in presence of exterior flame. The ignition temperature of polycarbonate sheets is 490ºC (915ºF), and PVC sheets 391ºC (736ºF). Both materials are self extinguishing, and fire will decay when the exterior flame source is removed. Compared to PC and PVC, acrylic sheets are more flammable.

Yes. Plastic sheets expand with heat, and shrink with cold. As engineering plastics, PC and PVC demonstrate limited expansion/contraction Vs other plastics, however this change in dimensions should be considered. The use of enlarged screw holes in corrugated sheets (and aluminum profiles in multi-wall and solid sheets) are standard methods that should be followed. Always use the guidance in Polyvalley installation instructions.